Tränkle Turning Technology has a worldwide reputation for top quality in the development and production of high-quality precision turned parts, valves and assemblies based on turned parts. Now in its fourth generation, our medium-sized family business was originally founded as long ago as 1889.

About us

From the Black Forest out into the world

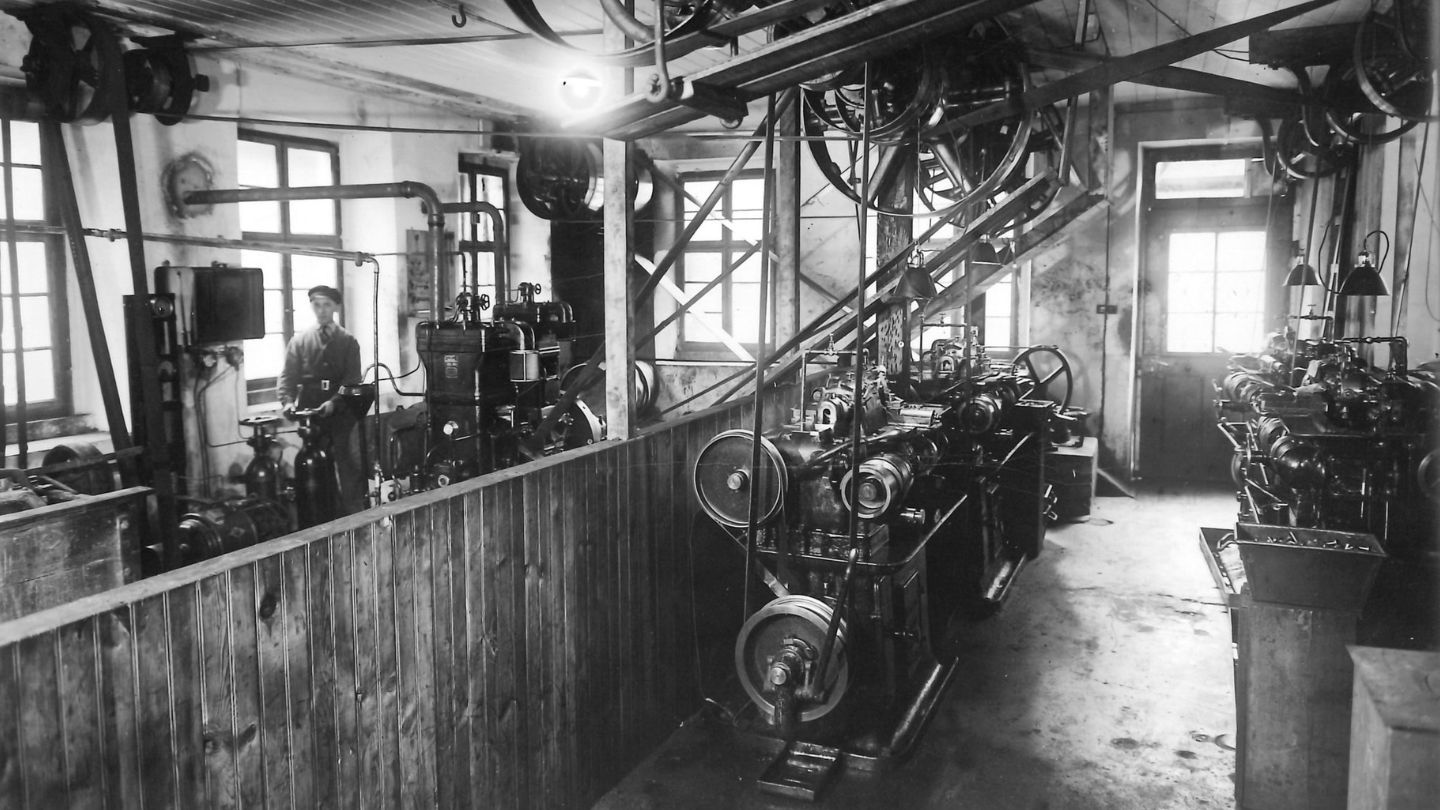

Here at our Triberg and Elzach sites in the Black Forest – one of the Germany’s most scenic regions – we manufacture more than 1,000,000 components with a diameter of up to 65 mm every day. We process non-ferrous metals such as brass and aluminium, as well as general purpose steel, stainless steels and special alloys.

Thanks to our more than 200 longstanding and highly qualified employees, we are able to offer a wide range of services – from development to production, set-up, surface treatment and logistics. Our products are used wherever precision, innovation, cost-effectiveness and the reliable realisation of large series are required. Whether sanitary fittings, heating thermostats, plug-in couplings, control units, hydraulic units or oil pumps: we offer impressive high-precision solutions in particular for the sanitary, building services, automotive and electrical engineering sectors.

Facts

Facts and figures

200

Employees

1 mill

turned parts per day

100

Lathes

135

Years of experience

Philosophy

Embracing real values – creating genuine value

At Tränkle Turning Technology, values such as dependability, flexibility and fairness are not just empty phrases but a living tradition that we embrace in practice. Outstanding environmental awareness and social responsibility are principles we have upheld for four generations. Our flat hierarchies and open-door policy promote teamwork and the exchange of ideas. Our primary goal is to maximise quality in products, service and innovation. We maintain honest and long-term partnerships with our suppliers, employees and customers – after all, the key to lasting success is the satisfaction of our customers.

Sustainability

Our investment in the future

The people of the Black Forest have always been well-known for their inventive flair, conscientious attitude and hard-working nature – qualities that we expect from and encourage in our employees, too. Independent and responsible action are an integral part of this. Responsibility is also reflected in our high level of environmental awareness – something that has always come naturally to us as a tradition-steeped company situated in the heart of the Southern Black Forest Nature Park. Rather than focusing on extreme growth, Tränkle seeks to maintain continuity and sustainability.

This is why environmental compatibility is a key factor when it comes to selecting our suppliers and developing our products. In our manufacturing processes we utilise the very latest technologies to reduce energy consumption and conserve resources. Our high-performance photovoltaic system with almost 500 kWp and our carbon-neutral heating system already enable us to save enormous quantities of CO2. Our long-term goal is a production process that is completely carbon-neutral.

It has long been standard for Tränkle to fulfil industry and country-specific environmental guidelines and ensure REACH and RoHS compliance for the materials we use, likewise the use of lead-free or low-lead materials.

MAXIMUM PRECISION HAS A REASON

Tränkle has several:

135 years

of experience

We’re familiar with the markets and the processes. We’ve served our customers successfully for decades.

Specialist counselling &

Services

Covering all processes, an experienced contact person will advise you on materials, manufacturing options, and trends in technologies and markets.

Quantity

with quality

High-volume production at the highest level of quality. More than 100 lathes produce 1,000,000 turned parts every day.

Maximum

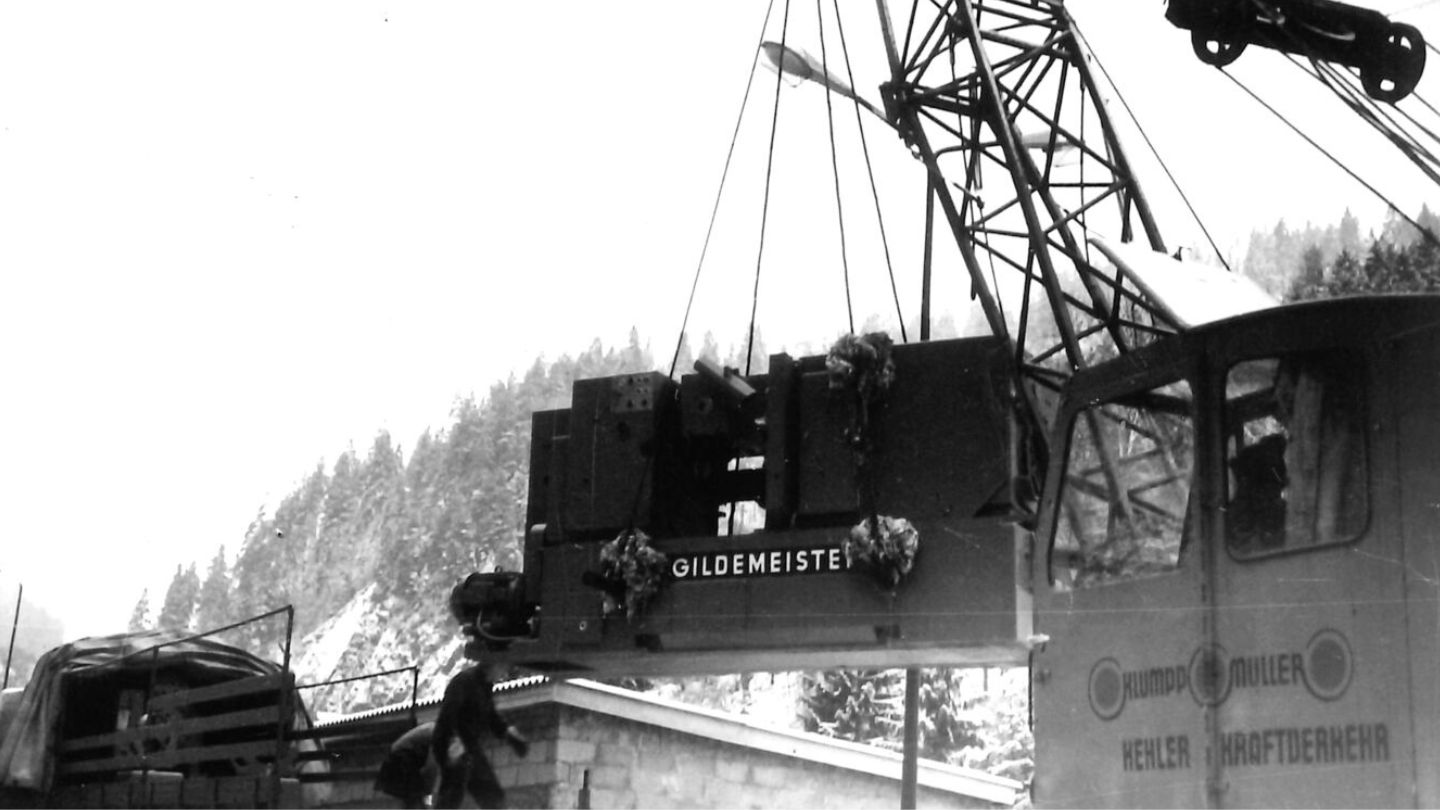

flexibility

We’re extremely agile – thanks to homogeneous machinery, sound supplier relationships and our own in-house toolmaking facilities.